Steel Doka system can be used for ordinary as well as for flat slab.

A) ADVANTAGES OF USING STEEL DOKA SHUTTERING SYSTEM

1) Better finish.

2) Ease of erection and removal of shuttering.

3) Long lasting. (many repetitions )

4) Can be used for any slab thickness.

5) Engineered design calculations.

6) Components of system can be used for other purpose also.

7) Easy checking.

8) Controlled deflection.

B) STEEL DOKA SYSTEM CONSIST OF,

1) Film face Plywood 12mm thick

2) M.S. 4 way head

3) ISLB 100 x 50 mm Joist, 2.2m long

4) ISLB 100 x 50 mm Bearer, 1.5m long.

5) G.I Acrow Telescopic Prop. (2.44m – 4m).

6) G.I. Tripods.

7) M.S. Bracing pipes.

C) General arrangement of system is as shown in picture.

Plywood is supported by joist (ISLB 100x50)

Joist is supported by Bearer (ISLB 100x50)

Bearer is supported by Acrow props.

D) SEQUENCE OF ERECTIONS

In case of Grade slab, one may have to provide temporary PCC to have firm base on which

shuttering can rest. This is very important in case of flat slabs with higher loads.

1) Start erecting props with spacing as per approved design. G.I tripods are used to keep props

standing independently as seen in picture. G.I. tripods do not carry any loads. Make sure that all

props are in plumb and in line. Tile line Dori on first and last prop, and adjust all props

accordingly. Provide bracing to all props which are opened more than 3.65m. bracing shall be

provided on the inner tube approx 225mm above threading level.

2) Put 4 way heads on props. 4-way heads are provided to facilitate overlapping of Bearers and to

provide lateral stability to bearers.

3) Bearers are laid over 4 way heads. Use Bearers of correct length. ( normally1.5m )

4) Start placing joist over bearer as seen in picture. All joists shall be placed parallel and spacing as

per approved designs.

5) Now plywood can be laid over joists. Provide joists at closer spacing near plywood joints. Slab

plywood shall be nailed to beam sides @ 225mm c/c. Also, provide 3” wide masking tape on the

plywood joints to prevent slurry leakage from the joints.

6) If due to curling, one may find plywood sheet corners getting uplifted. Than put stitching plywood

piece till reinforcement is placed in position.

7) Leave appropriate space between beam sides and joists/ bearers so that they do not obstruct

deshuttering of beam sides.

8) Below Picture showing shuttering of drop panels in case of flat slab shuttering.

9) De shuttering of slab shall be done only after required strength is achieved in 5 days.

10) Tool can be used to turn nut of props. This makes it easy for carpenters to erect and deshutter

props, especially when they are large in numbers.

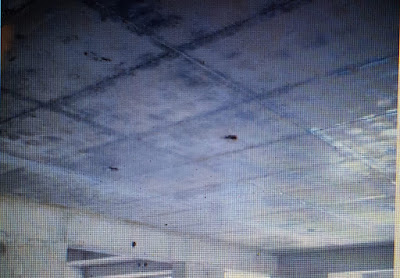

11) Remove masking tapes from the ceiling of slab, after deshuttering.

12) Picture showing slab ceiling finish.

13) SHUTTERING MATERIAL MAINTENANCE

1) All shuttering materials shall be stacked properly and shall not be thrown down while shuttering.

2) All shuttering materials shall be used for the specified purpose only.

3) Also contractor shall return shuttering materials after cleaning the same.

4) Any props with rusted base shall be immediately removed and repaired.

5) contractor shall regularly apply oil on the threading of outer props for smooth functioning of nut.No cracked nuts shall be used otherwise it will result in slip failure of props.

6) Oil shall be applied on bottom 9” portion of props to avoid any kind of rusting. Use plastic bucket with oil and immerse props for bottom 9” so that oil can penetrate inside props also.

Comments

Post a Comment