PAVER BLOCK.WHAT IS THE PROCEDURE FOR PAVER BLOCK FIXING ?? W.B.M (WATER BOND MACADAM)

- Get link

- X

- Other Apps

Paver

blocks.

1- Study the Arch drawing and services drawings to find out levels, and

gradient of road. Paver

block typical section is as shown below. Details can change depending on strata

and vehicular loads.

Preparation of Subgrade

3.1) Cutting/filling of subgrade to required level, gradient and camber.

3.2) Carry out lime stabilization treatment for sub base as per specifications given below.( Where ever specified ).

3.2.1) Excavate up to required level & Gradient.

3.2.2) Loosen the soil up to 200 / 300 mm below the required level preferably with JCB / Tractor having Pulversing tool attachment.

3.2.3) Spread the lime over the loose soil @ 5kg / sq.mtr. and mix the lime and soil by using spade and sprinkle water over it.

3.2.4) No traffic should be allowed to move over it other than the mixing equipments till mixing is completed.

3.2.5) Immediately after spreading, Grading & Leveling of the mixed material compaction shall be carried out with approved equipment.

3.2.6) Rolling with Vibratory roller 8 - 10 MT shall commence at edges & progress towards the centre.

3.2.7) Compaction shall continue until the density achieved is at least 95% of the maximum Proctor density for the material.

3.2.8) Compaction of Lime stabilized material should be completed within 3 hrs.

3.2.9) The sub base course shall be cured for minimum 7 days.

3.2.10) Carry out watering and rolling with 10-12 T roller / 8T vibratory Roller to achieve 95 % proctor Density.

3.2.11)Carry out Proctor density test to check compaction. And if value is less than 95 %, than carry out rolling till 95 % is achieved. Suppose, in case of Clayey soil, we do not get 95% Procter Density, then carry out 30 passes of Roller, to get the desired results.

4- W.B.M. ( Water bound Macadam )

4.1) Total 4 layers of W.B.M. shall be done. ( Refer Sketch ). This depends on type/nature of strata.

4.2) First two layers of Hand Broken Metal 90-60 mm size and balance two layers with Hand Broken Metal 60-40 mm size as shown in sketch.

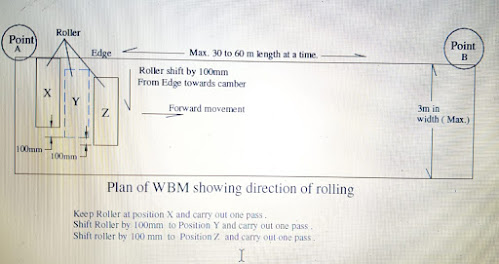

4.3) Laying of 80mm thick Hand Broken Metal ( compacted thickness ) W.B.M. in max 30 to 60 m length and in 3m width ( Max ) at a time as shown in sketch given below.

4.4) Carry out Dry rolling of first pass ( One pass means traveling from point A towards point B and from point B to point A ).

4.5) Spread stone dust for the full length and width ensuring that voids between stones are filled up with stone dust.

4.6) Again carry out dry rolling with one pass

4.7) Sprinkling of water shall be carried out with sprinkler arrangement on the back of water tanker to ensure uniform spreading of water.

4.8) Carry out rolling of W.B.M. to ensure full compaction. Min. 30 passes shall be carried out for proper compaction.

4.9) Keep shifting roller by 100mm as shown in sketch after each pass. Rolling shall start from Edge towards camber of the road. This is because on the edge there is s Storm Water Drain (S.W.D.) to support W.B.M...

4.11) Follow the same procedure for all the layers of the W.B.M..

4.12) Clean top surface of the last layer of W.B.M. to remove excess powder.

4.13)Carry out final compacted levels of the W.B.M. with dumpy level to cross check levels of W.B.M. and carry out necessary corrections if required.

5- Paver

blocks fixing procedure.

First

of all make level pads using paver block and sand ( unscreened ) according to

required gradient, slope and camber as seen in picture. Thickness of sand

bedding shall be 40mm. If thickness is more than 40mm, carry out rectification

of WBM.

6- Make

sure that curb stone/stoppers are provided on sides to restrain paver blocks

from movement.

7- Spread

sand (unscreened) loosely and uniformly over the surface using Aluminum Patti.

Do not compact the sand. Sand to be used shall be dry. Grit powder can also be

used in place of river sand. As far as possible try to avoid fixing of paver

blocks in monsoon.

8- Start

fixing paver blocks as per approved colour, thickness and pattern and hammer

the blocks with wooden mallet. Make sure that no broken paver blocks are used.

9- Provide temporary end stopper and the end of the work so

that no paver blocks move and get loose. On commencement of work, remove these

temporary stopper and continue paver blocks

fixing.

10-Cut

blocks of the required size and shape

on the edges and see that gap between kerb stone and paver is min. and uniform.

11- Provide straight line joint between old

and new paver block.

12- Spread fine sand (fineness suitable to

penetrate 2mm gap between paver blocks).

13- Carry

out compaction of the paver blocks using

plate compactor, to see that fine sand enters

into the gaps between paver blocks. This ensures complete interlocking of

paver blocks.

14- Remove excess sand/grit powder.

15- Now Road can be opened for traffic.

- Get link

- X

- Other Apps

Comments

Post a Comment